Product Review: 22ple VS1 Final Coat (Part 2)

by Ivan RajicIn part 1 of my product review on 22ple VS1 Final Coat, I went over some application testing I performed on a Ferrari F12. Everything went very smoothly and I ended up liking the VS1 Final Coat quite a bit. That said, I of course wanted to do some more product testing and of course in worse conditions, so I decided to try this same test out on a much hotter and humid day, which was around 90 degrees and 80+ humidity. It was done on a freshly polished trunk, right after I used CarPro’s Eraser to remove any oils.

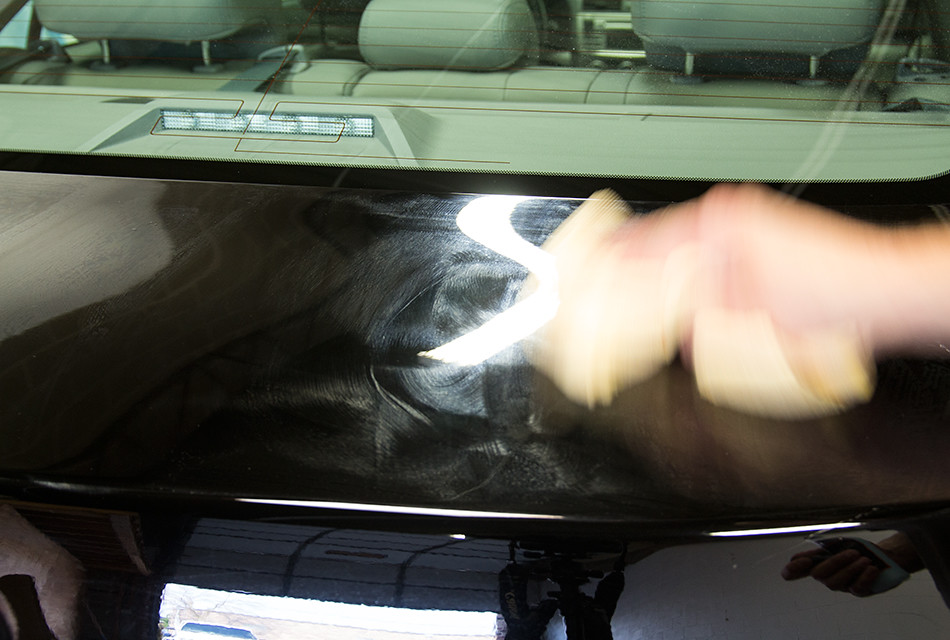

I applied a somewhat heavy coat fearing it would dry very quickly…

Which it surely did! In about 2.5-3 minute it was completely dried and hazed…

I started to remove at around 3.5 minutes…

And that’s when my assumptions came true. VS1 had completely dried up much quicker than the previous time I used it and it was a pain to remove…

But as before, with a bit more product sprayed onto a clean side of the towel, it easily started to come off and leave a great finish behind…

Soon after I did all this testing with the product, I received instructions stating that you should remove it at around 3 minutes. I believe that roughly matches my findings in that you can probably apply normally (not too thick) and remove at around 3 minutes. In warmer temps, I would recommend doing a test spot at 1.5-2 minutes just so you don’t end up with a headache later on, but then again, it’s extremely easy to remove the dried up residue that it may be just fine to wait 3 minutes to make sure the product settles long enough. In short, I’d follow the instructions, but at the same time do a bit of your own testing if temperature/humidity is fairly low or high.

Next I wanted to briefly discuss the application and amount of product. The applicators have a very nice foam material that easily glides over the paint and gets saturated with product after only a few small sections so that not a lot is needed as you go around the car…

You can either spray onto the paint or the applicator pad. If spraying onto the paint, I like to spray as close as possible to the paint (maybe 3-4 inches away) so as to avoid overspray onto other panels or glass as well as to have a more concentrated amount of product to spread out…

Even if spraying directly onto the paint, I would recommend 1-2 “primer sprays” onto the applicator pad so as to avoid any spreading issues with a dry applicator.

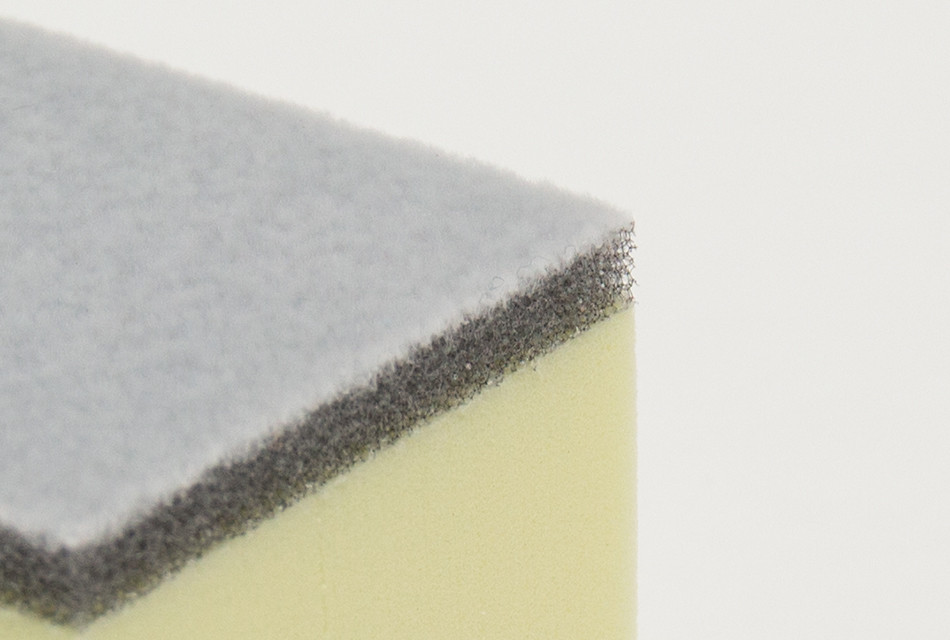

Once the product is on the paint and/or applicator, simply apply with slow back and forth motions to spread it evenly. Faster arm movement doesn’t really work here as the applicator has an edge that doesn’t get saturated (mentioned below in the Pros/Cons section), so moving quickly onto a dry section of paint may result in the applicator block stopping due to trying to spread it too quickly. As mentioned above, after a few panels the applicator foam gets well saturated and you’re able to apply it easier, only having to spray new product onto the paint. Here’s a photo of the edge of the applicator pad…

Next I wanted to give a quick pros and cons list for the 22PLE VS1 Final Coat.

Pros:

- The spray head makes this application a breeze. Whether you decide to spray on the applicator pad or the paint, the product easily goes on and spreads evenly.

- Speaking of spreading, it spreads onto the paint very easily and evenly, especially when you go slow and saturate the applicator well.

- I haven’t performed any full car jobs with the product yet, but based on the amount of experimental applications I’ve done, there is a good amount of product in the bottle and a great value for the price.

- When it dries, it’s very noticeable. It starts wet, then slowly dries to a haze throughout the area to which it was applied. It seems the thinner areas dry quicker than the thicker, which would make sense, so it allows you to see where you may be applying it unevenly to the panel.

- At 10-15 minutes it wipes off just fine when applied thick enough. However, this was at a certain temperature. I want to do more testing to see the durability of the product when applied in different manners and removed at certain times, but I would recommend removing anywhere between 3-10 minutes, after the section fully dries to a haze. Probably 3-5 minutes when it’s warmer or more humid.

- As with the VX1 coating, when you leave it on for too long and it leaves spots, it’s very easy to remove it by reapplying. As mentioned above, having a spray head for VS1 makes both application and reapplication a very easy task, almost as simple as applying a quick detailer or spray wax.

- Long enough dry time where you don’t need to worry about highspots much. I like the idea of using it as a spray sealant on top of a washed car and not worrying about wax grease, streaking, etc. Simply apply to a few panels, go back and remove, then finish the rest of the car in the same manner.

- You can control the dry time with the thickness of applied product. Not sure how much this will sacrifice the durability of the coating, but it is an option if you’re in a rush.

Cons:

- Spray pattern is a bit odd and not to my liking. I’ll have to do some more testing with it and maybe find the sweet spot, but as of now I don’t like how it comes out. Not sure how to explain this best, but I’ll try. When spraying VS1, it comes out in a circle pattern, but it only creates a circle outline where it’s sprayed, without filling the middle of the circle. This becomes an issue less when spraying onto the paint as you can simply spread the product however you want, but when spraying onto the applicator it needs to be really close to the foam or it will spray to the sides/around the applicator, without leaving much in the center. I wouldn’t call this a big Con, just something of mild annoyance I noticed.

- As good as the dry time is, I would prefer a quicker dry time. Considering it’s to be used as a maintenance product, similar to a spray sealant, I would like to be able to spray and apply to an entire hood, then remove right after. Reason being, it was in the 80s and mild humidity when I found it to dry well at around 10 minutes or so. However, I believe that in a colder situation, it make take much longer to dry. This is something I haven’t experienced yet as I have only tried it in 70-90 degree weather, but am looking forward to how it acts when the winter hits in Chicago and I apply it in 55-60 degree weather with no humidity.

- Last of the cons, which is more of a criticism based on my experience, is the applicator pad. The foam on it is great and glides over the paint well once properly saturated. The block is also easy to hold and is perfectly firm, while the interface foam allows for a cushion between the block and the applicator bottom which holds the product. Overall it’s a good design, however, I found two issues that were bothering me. One was that the foam on the bottom didn’t wrap around the edges. As mentioned above, because it abruptly ends at the edge of the applicator, the entire applicator can skip when hitting a piece of dry paint since the edge can’t be saturated with product. I think a solution would be to either wrap the edge of the application material or to simply eliminate it from the overall block and include small “towels” made of the same material that I can put onto the applicator itself, wrapping the edges. The other issue I had was that the block was simply too thick to get into some areas (under mirrors mainly). Ultimately, I would like to see the block around 1/2 the current size to take care of this, otherwise having individual towels that can be used without the block is a solution. To repeat, I really don’t think there’s anything wrong with the applicator and I liked using it (slow arm movement is fine and rarely if ever skips on the dry paint as mentioned), I just feel the design can get better overall.

As you can see, only a couple, if you can even call them cons!

Conclusion

Well that’s all I got, as if it isn’t too much :). Overall, I’m very pleased with VS1 Final Coat and see it becoming a regular for sealing purposes. Whether topping a coated vehicle or using as a sort of spray sealant, it should have good durability and look great, with a completely painless application process. I have since used it a few times as a sealant and it took only 10-15% more time than a regular spray wax/sealant, such as Optimum Car Wax or CarPro Reload. I believe it was because the removal of VS1 is extremely easy, so there’s no time wasted. Again, great product that impressed me very much and I am looking forward to seeing how it holds up in the various ways I’ve applied it. Time will tell!

Great Review Ivan! I look forward to trying the VS1 Final Coat from 22PLE.

I believe this is exactly what 22PLE needed.

How has durability been? Any bead shots? I’ve been using Kamikaze Overcoat, absolutely love it because it can be used wet or dry, a little goes a long way, and it’s held up very well only being refreshed once in the 4 months I’ve been using it, and that’s just because of my OCD, not that it needed it. I have Gtechniq C1/Exo V2 under the Overcoat, and it was mainly to help prevent spotting because the wife’s jeep sits out at the airport for 2 weeks sometimes. I’m anxious to try this over 22PLE on another car I did, and hoping it will help prevent some spotting I’ve seen on cars that sit out a lot(with 22 and Gtechniq). Did you try spraying it on a microfiber and applying like that? That’s how I use the Kamikaze, and it’s pretty effortless. I have some Final Coat on order and coming my way to try over a coating, and as just a sealant, see if it performs like Kamikaze and I can save a few bucks as I’m not a professional and do detailing on the side for family and friends. Nice review by the way.

I haven’t seen the car yet as it was stored recently for the winter, but I’m testing durability on a friend’s and my own car as well. So far so good after almost 9 weeks.

I did not try applying it as a quick spray wax just yet, but that’s how I plan on using it and will be testing durability of such application very soon. I’m hoping it gives a couple of months from that quick method, but won’t know for a while. Definitely let us know how you like it when you try it Joe.

what’s the “cure” time on this before getting wet? Can you seal a car and go right out in the rain, or give it a few hours?

I would surely let it sit for a few hours Joe. I would say at least 30-60 minutes. I’ll try and find out if there are specific recommendations for cure time from the manufacturer.

Thanks, that’s the only thing unknown so far about this product. My truck sits out 24/7, and sometimes when I leave the office I pull it in the shop for a wash just because(even if it’s raining or snowing out), and sometimes I don’t have time for a product to “cure”. I purchased Gyeon wetcoat so I can top up the base coat, hose it down, blow it, and a quick dry wipe and it’s good. I don’t have time usually to go through the whole wash process as normal. If I could use this like Kamikaze wetcoat where it can get wet right away, or very soon after application, this will be my “go to” for my truck.

first off I like this product and would compare the bead quality to Kamikaze overcoat, they both produce very tight beads (almost as tight as EXO) the final coat does feel more slick though. The only issue I have had so far with this product is some streaking on very dark colors. I have tried many different methods and timings but still have this problem. Has anyone had this same issue with the final coat? Any feedback would be appreciated.

thanks

I’m sorry I didn’t read your full post the other day. Now I have to do some repolishing…oh well. Anyway yes I had problems on a black car. Not only streaking but dark blotches. Like you I tried everything. Finally went over it with a damp rag then buffed and it took care of it. Like you I’ve tried everything. I thought it must be something I was doing but I am experienced in coatings. I notice in this review the product was only used on bare paint. Were you using on bare paint or topping VX? The black car I did I was topping 3 month old Pro1 because the customer wanted a slick feeling. On my car where I did most of the testing it was going on Pro2 that was from 24-72 hours old. I assumed it was something I was doing…still could be…but glad I’m not the only one having issues.

Which of the following sacrificial coatings do you think is best and why:

22ple VS1 Final Coat, CarPro Reload Spray Sealant, GTechniq C2 V3 Liquid Crystal.

Thank you very much for the advice.

Mark

Hi Mark,

I haven’t tried the GTechniq product so I really can’t speak to it. Reload I’m not a fan of simply because I’ve had issues with application, such as streaking too much. So of the 3, I’m partial to VS1 Final coat as I’ve had the best experience with it. Wish I could be of more help.

I assume you have used this product over VX Pro and Pro 2. Have you used it over these coatings on a dark colored vehicle, especially black? Like another user I had issues with streaking. On a black Infinity putting it over VX Pro that had been on the car for 3-4 months it was actually leaving dark blotches regardless of applicator, time, etc. I ended up having to take a damp microfiber and buff to even it out/remove it. I had to use GTechniq C2v3 over it to give the customer the slick feeling he wanted. This was a less than ideal application but I’d did work. I don’t think the durability is going to be very good because of the way the application went. Any insight into this problem or how to avoid this problem would be greatly appreciated.

Unfortunately I haven’t had the same issues Dave (well fortunately for me!) so I can’t really say what went wrong. How long did you leave it on for and was there anything else on the paint between that application and the coating application 3-4 months back?