Museum Detailing 101

by Mike CardenasFor professional detailers and enthusiasts alike, safety and preservation is a key element in the detailing process. However, when it comes to detailing a vehicle in a museum, nothing is more crucial than those two elements. As a Sonax team member of the Indianapolis Motor Speedway Museum Preservation Team, I’ve been fortunate to detail some amazing and legendary historic vehicles. Sonax USA is the official car care supplier for the museum located within the 2.5 mile oval track that is the legendary Indianapolis Motor Speedway. Within the museum, you’ll find anything from past winning Indy 500 race cars to vintage and extremely rare automobiles. Such as the 1954 Mercedes-Benz W196 grand prix race car driven by legendary drivers Juan Manuel Fangio and Sterling Moss, one of only 2 in existence! The other is in the museum at Mercedes-Benz in Germany. A 1964 Ferrari 250 LM that was the winner of the 1965 race at the 24 hours at Le Mans, the last time Ferrari won an overall victory at Le Mans. To add to a Hollywood come to life story, a 1966 Ford GT40 No. 4 that raced at the 24 hours at Le Mans in 1966.

1954 Mercedes-Benz Formula 1 W196 Streamliner driven by Juan Manuel Fangio

24 Hours at Le Mans racers, 1964 Ferrari 250 LM and the 1966 Ford GT40 No. 4

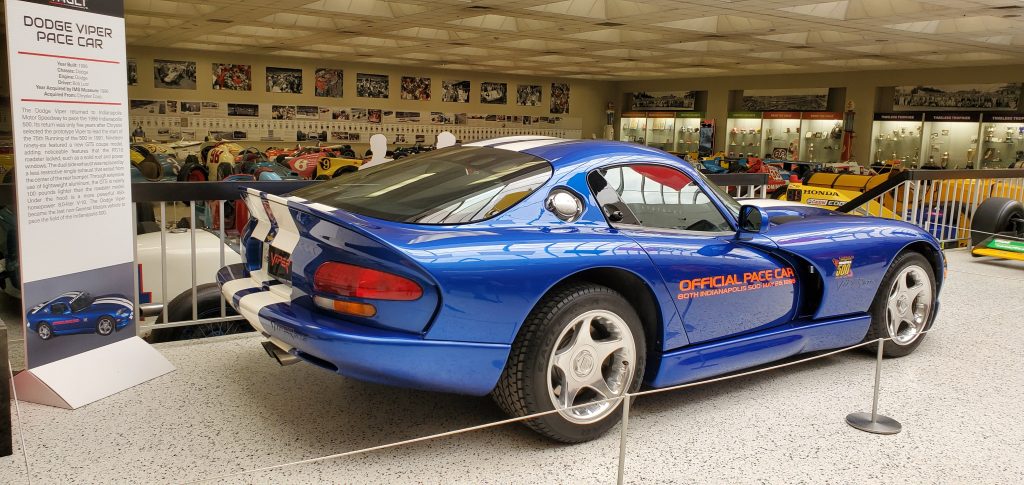

As professional detailers, we often work some pretty expensive vehicles, but working on something that is historic and down right irreplaceable can be an intimidating situation. After having worked on several projects for museums in the past, I wanted to share some helpful fundamental tips for those given the opportunity to work on such a project. I recently worked with the team at Sonax USA and Top Line Detail from Terre Haute, Indiana on a 1996 Dodge Viper that was the official Pace Car for the 80th running of the Indy 500. The vehicle was donated by the Chrysler Corporation to the museum in 1996 and was to become the last non-General Motors pace car at the Indy 500. Needless to say, this was a very important vehicle from the vault at the Indianapolis Motor Speedway Museum and it had never been professionally detailed.

The vehicle was on display on the floor at the museum and did have upon inspection swirls and scratches. It did have some level of gloss with little oxidation since it has been indoors since it ran as a pace car during the 1996 Indianapolis 500. The museum tasked us with finding a way to enhance the gloss and presentation of the Viper, all while keeping the preservation and safety of the vehicle a priority.

In most cases, detailing a vehicle in a museum will be done off the museum display floor. In other cases, I’ve always done them at a different part of the facility away from the public. This can make things a bit more comfortable for the detailer as they can work in an environment similar to working at their shop. For us on this particular project, we would be working center stage at the museum during opening hours. The upmost professionalism was also key, not that it never is, but when you’re now part of the display for the day it has to be on everyone’s mind.

What to Pack?

For this type of detailing, there are some essentials that you will need to bring with you. And of course, as detailers its easy for us to over pack the first time out. For those who are usually in the mobile realm, this will certainly be an easier task. Keep in mind that most likely, you will not be able to wash the vehicle in the traditional sense. This is a completely different approach. Don’t rely on the museum to provide you with anything other than the vehicle, the facility and electricity. Here’s a short list of some basic essentials that we brought along for working on the Viper.

- Extension Cords (about 6 to 8 cords were brought in)

- Scangrip Lights (such as the Scangrip Multimatch 3 )

- Machine Polishers and Tools (Flex North America is an official sponsor)

- Polishing Pads for cutting, polishing and finishing

- A Rinse-Free Wash System

- Detailing Spray (such as Sonax Brilliant Shine Detailer )

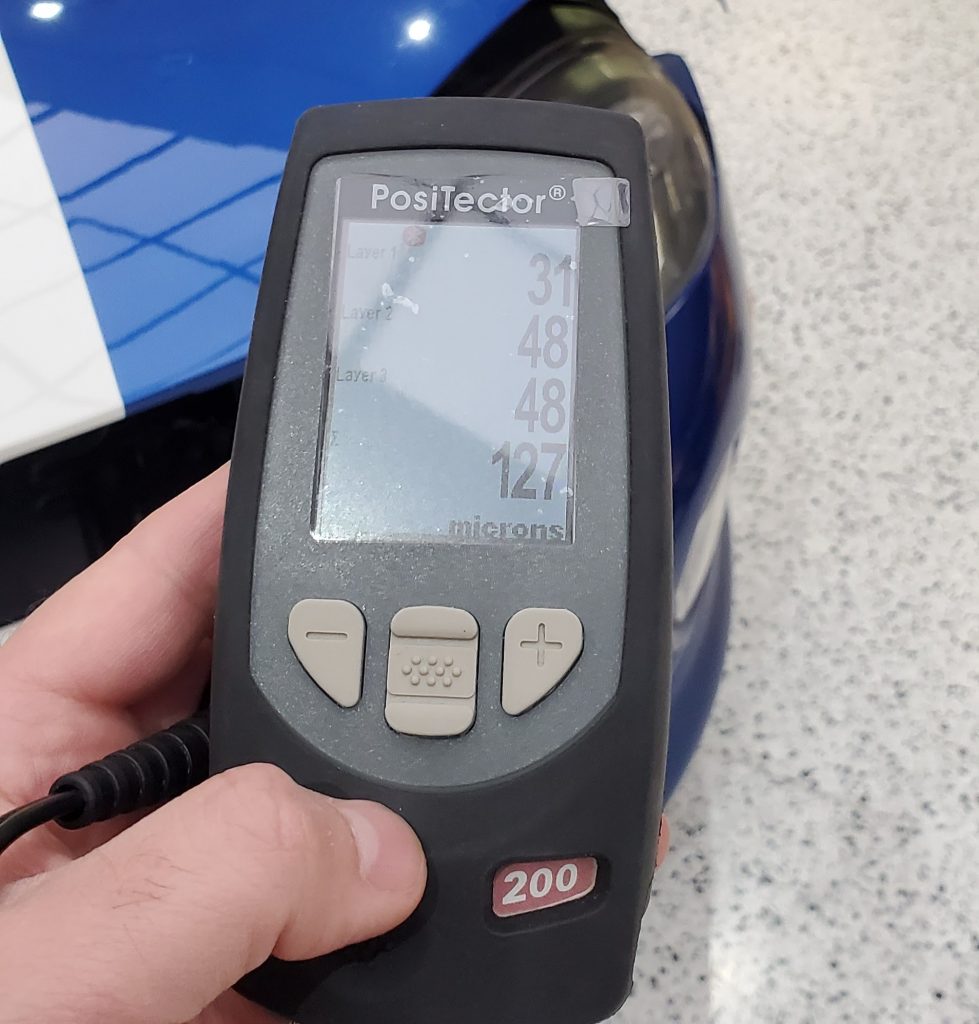

- Paint Thickness Gauge (we used the Delfesko Positector 200 )

- Various Microfiber towels for paint, glass and misc. surfaces

- Masking tape

- Glass Cleaner (we used Sonax Glass Cleaner )

- Compounds and Polishes (We used the new Sonax Ultimate Cut and Sonax 04-06 )

- Detailer’s Helper belts as a replacement for detailing carts

- Paint prep spray.

- Metal Polish

- Paint Sealant (we used Sonax Polymer Net Shield )

- Tire Dressing ( we used Sonax Tire Gloss Gel )

Just some of the products used on this project

Average clear coat thickness was 35 microns on the Viper

The Approach

Jason Vansickle is one of the curators at the museum and he filled us in on some of the history of the vehicle and what the museum wanted to achieve in terms of detailing. So we then unpacked our supplies and began setting up to work. Before any of the work could begin, we had to assess the condition of the vehicle and look for any hazards like loose paint, trim or damage. The next thing was to use a paint gauge to measure the thickness of the paint as this was a purpose built vehicle and we wanted to make sure we had an idea of what we were working with in terms of paint. Because the vehicle is mainly carbon fiber, fiberglass and plastic, the Delfesko Positector 200 was a valuable tool to use. Special thanks to my friends at Paintcorrection.co for their support with the Positector 200.

Once the measurements were made, the team began to do a rinse-less wash and begin the decontamination process. The team at Topline Detail then began the process of masking off trim and various areas for machine polishing. The paint was swirled and in some areas this was extremely severe and was going to need some attention. The goal was to restore gloss safely while keeping preservation in mind. So I tested a few setups on a rear quarter panel and we devised a strategy to address the heavily swirled areas with a 2 step process of Sonax Ultimate Cut and Sonax 04-06 as the paint was very hard. Keeping in mind that our approach was to remove as many imperfections with minimal passes to maintain as much of the paint thickness as possible. For the remaining areas of the Viper, we went with a one-step correction using Sonax Perfect Finish. We then split up the vehicle into 4 sections and we began the paint polishing process. Rob and Cole from Sonax USA tackled on other areas of the vehicle while that process was taking place to keep the project moving along.

The Dodge Viper Pace Car in progress. And yes, that is Michael Schumacher’s Benetton F1 race car in the background.

“The approach” as I like to call it, is the strategy for how the project will be worked. We all do this when we detail any vehicle, but when you are working on a project as a team, it is very important that everyone work as a team and use the same products, techniques, speed, etc. to achieve a unison result. When done correctly, the end result will look as if one person had worked on the entire project. Teamwork on these projects is very important, which brings me to a subject that will also help when detailing in a museum setting.

Mental Focus and Awareness

The Preservation Team members laser-focused on the task at hand.

Many of us often get asked the question on working with expensive vehicles, “Aren’t you scared of burning through the paint or screwing something up?” and the answer is yes and yes. Although its something that we don’t like to think about. In my training classes, I always teach my students that polishing on these type of vehicles requires a high degree of focus and awareness. Concentrate and focus and what you are trying to do, not on what you don’t want to do. Much like playing golf, if you tell yourself and put it in your mind that you do not want to slice the ball, what tends to happen is that you do what? Slice the ball. Instead, focus on what you are trying to accomplish when detailing something that can seem intimidating. Keep your focus! Also, if you are working as a team, keep conversations to a minimum and keep from distracting those who are trying to keep laser focused on their task. This keeps everyone working efficiently and safely on the project. When working as a group or team setting, keep an open mind to helpful suggestions and tips from your fellow team members.

Preservation and Safety

Preservation and Safety is always one of the top priorities when working on a museum project. Of course, this also applies to all projects, but this is paramount when working on rare and priceless vehicles. When I discuss preservation in my training sessions, I always make the statement that “just because you can, doesn’t always mean you should” meaning that just because we know how to remove all of the swirls on the Viper, it doesn’t mean that it is necessary to do so. Know when to say when. As detailer’s this is a trap that many fall into and it has no place when detailing on a museum project. Remember that preservation is key!

The vehicle is on display and is in a museum for a reason and it isn’t to necessarily display your killer paint correction skills. I’ve heard of countless situations where the detailer was pushing the paint to the limit to achieve perfection, only have burned through the clear. Paint correction is a huge component of detailing in this type of environment, but it is throttled way back from the norm because preservation is the pinnacle objective and responsibility of the detailer. The museum has the responsibility of preserving a piece of history for generations to come. Who are we to contradict that by selfishly satisfying our own paint correction needs?

A before picture of the hood of the Viper Pace Car

This is after some imperfection removal. An improvement with an appropriate level of paint correction.

Some RIDS or “Really Intense Deep Scratches” on the Dodge Viper. These were too deep to address on such a project.

Final Stage

Rob McCrary – Managing Director at Sonax USA applying Sonax Polymer Net Shield

Once the Viper was machine polished, the paint was prepped and we installed Sonax Polymer Net Shield to give long-lasting protection and gloss. As a team, while some were applying Polymer Net Shield, others were cleaning glass, polishing metal work, applying tire gloss. Measuring the paint afterwards gave us many close to identical readings when we started, showing that we did our due diligence of paint preservation. Once the project was completed, we began wrapping up cords and putting everything away. With on-looking visitors to the museum, we proceeded to push the finished Viper into position where it was to be on display. The vehicle looked glossy and stood tall among the other legendary vehicles on display. The team at the Indianapolis Motor Speedway Museum were extremely pleased with the results of how the Viper Pace Car turned out.

The finished 1996 Dodge Viper Pace Car

In closing, there are some important things to remember when working in a museum environment. As professional detailers, we have a responsibility to preservation and safety. Keeping mentally focused with a delicate and professional approach when working on a historic vehicle. In some of the past projects we’ve worked at the museum a white glove approach is not surprisingly necessary. Pack what you feel you might need, but keeping in mind that you will most likely be working indoors the entire time. It goes without saying that cleanliness is important when working in such an environment. Lastly, breathe, relax and enjoy the process. Know that you are helping maintain something historic for future generations to enjoy.

The Indianapolis Motor Speedway Museum is recognized as one of the most highly regarded museums in the world dedicated to automobiles and auto racing. If you ever visit Indianapolis, I highly recommend paying a visit to the Indianapolis Motor Speedway Museum, check out the awesome collection of automobiles, memorabilia and even take a walk on the legendary track. If you’re up for it, the traditional “kiss the bricks” is an Indy must-do!

Great job Mike, it must be an honor to work on the museum cars!

Thank you Doug. Yes, it is quite an honor and a privilege.

So happy you are sharing this experience! Congrats on a tremendous honor too!

Thanks Greg!!

Awesome write up Mike – We are privileged to have you and Top Line Detailer as part of the Sonax family.

The privilege is all mine my friend! Thank you and the rest of the Sonax team for the continued support.