Although carbon fiber on vehicles can be considered as exotic materials, they fortunately do not require exotic maintenance tools, products, or techniques to keep them looking their best!

For the most part, you can and should care for your carbon fiber components no differently than you do your painted surfaces. You wash them the same as you would paint, you can polish them to remove swirls and increase gloss, and you can wax and seal them just the same as well.

With the majority of carbon fiber that I have worked with, I have generally found the clear coat on them to be a bit on the soft side. Given this, I will always start with the least aggressive method and work my way up as necessary to achieve the desired results.

Since aftermarket carbon fiber hoods are probably the most common items available, I’ll use that as an example of how to care for them. For regular maintenance, wash and dry as you would the rest of the vehicle, and apply your wax or sealant of choice. Several times per year (especially in the northern states), you will want to use a clay bar to remove embedded contaminants…just as you would with the rest of the car. And when you want to polish by machine to remove swirls and/or restore gloss and clarity, then I would recommend using finer grade polishes such as Menzerna 106FA or Meguiars M205 and lighter polishing pads such as a Black, White, or Tangerine Lake Country pad.

Below is an example of carbon fiber that was heavily swirled with holograms (most likely from the factory since the car only had 800 miles on it!). This was on a Ferrari F430 Scuderia that has a lot of carbon fiber on the car. When I did my initial inspection on the interior of the car, I quickly noticed that the CF door panels were a bit hazy, and when I shined my lights on them I saw just how bad they were. With a few quick steps however, I was able to bring the color and gloss of the carbon fiber to a whole new level and it looked absolutely stunning when I was finished.

Take a look at how bad the swirls, haze, and holograms were before:

First I thoroughly cleaned the surface area using a spray bottle with Optimum No Rinse, and dried it off. Then I taped off all trim and mounting hardware. When it was ready, I chose Meguiars M205 with a 4″ Tangerine Hydro-Tech pad (cuts better than white, but finishes down almost as good as black), and used my Porter Cable 7424XP D/A polisher. The main reason I chose the PC over my Makita rotary is because it is smaller and easier to work with in tight areas. After just one pass, this combination was able to remove probably 95% of all defects, and I immediately noticed a big difference in the color with all of the hazing safely removed.

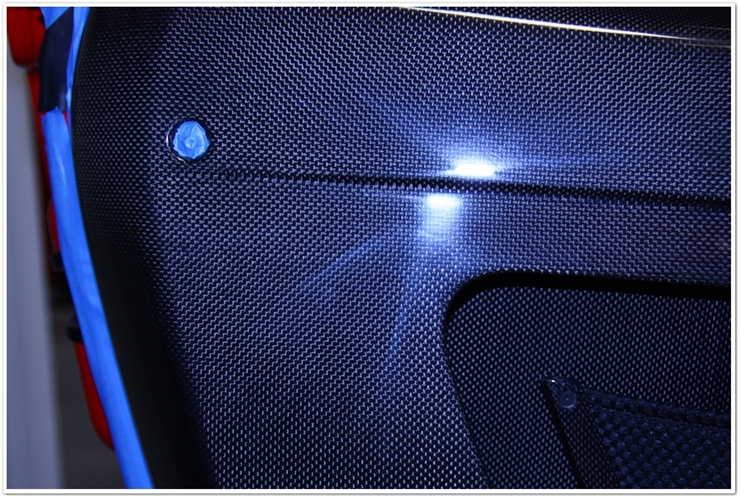

After one pass of polish, but before applying a sealant:

After polishing I wiped it down with Meguiars M34 Final Inspection to remove all of the residue from the polish, and then topped it off with Blackfire’s Wet Diamond sealant. This added even more gloss along with a layer of durable protection as well.

So the moral of the story here is to not be afraid to care for and polish your carbon fiber…it needs love just like the paint on your car does! Just be gentle with it, no harsh chemicals, and use fine grade polishes and pads when performing defect removal.

Buy Products From This Article

Purchase the products used in this article individually or in one convenient package here!