2016 Dodge Challenger Hellcat – New Car Prep: Factory Sanding Marks, Scratches, Swirls

by Zach McGovernThe owner of this vehicle contacted us regarding our Elite New Car Prep for his Hellcat which had just been shipped from the factory. He had requested that we take delivery of the vehicle shortly after it arrived so that it can be properly cleaned, polished, and protected from the start.

This vehicle arrived on a trailer from the dealership with just 24 miles on the odometer. Upon inspection it was clear that we had a very long journey ahead of us to get this brand new vehicle into good shape. We found machine sanding marks on every panel of the vehicle, heavier scratches on various panels, and some swirl marks throughout. Needless to say, this is not what we expected to see for a vehicle that had barely been driven, and was not touched by the dealership upon arrival.

The vehicle was delivered with a lot of dirt and grime on it, presumably from its trip from the factory to its new home.

I began with a thorough exterior wash and decontamination process to remove the contaminants that had settled on the paint. The vehicle was covered in a thick layer of foam to help loosen the dirt before washing. While the foam was dwelling, the cracks and crevices were cleaned with soft boars hair brushes, we then pressure rinsed the foam away, and proceeded with a 2 bucket wash.

After the wash process, the entire vehicle was clayed to remove any particles that had bonded to the paint.

With the paint clean, we turned our attention to the wheels and wheel wells. The vehicle was lifted, and the wheels were removed. The wheel wells and brakes were thoroughly cleaned using all purpose cleaner, degreaser, and various brushes. The calipers were then coated for additional protection.

The wheels were cleaned inside and out, and then coated with 22ple VM1 Extreme Wheel Coating for easier cleaning and added protection. We found this coating brought out more of the gold color in the wheels, which we really liked.

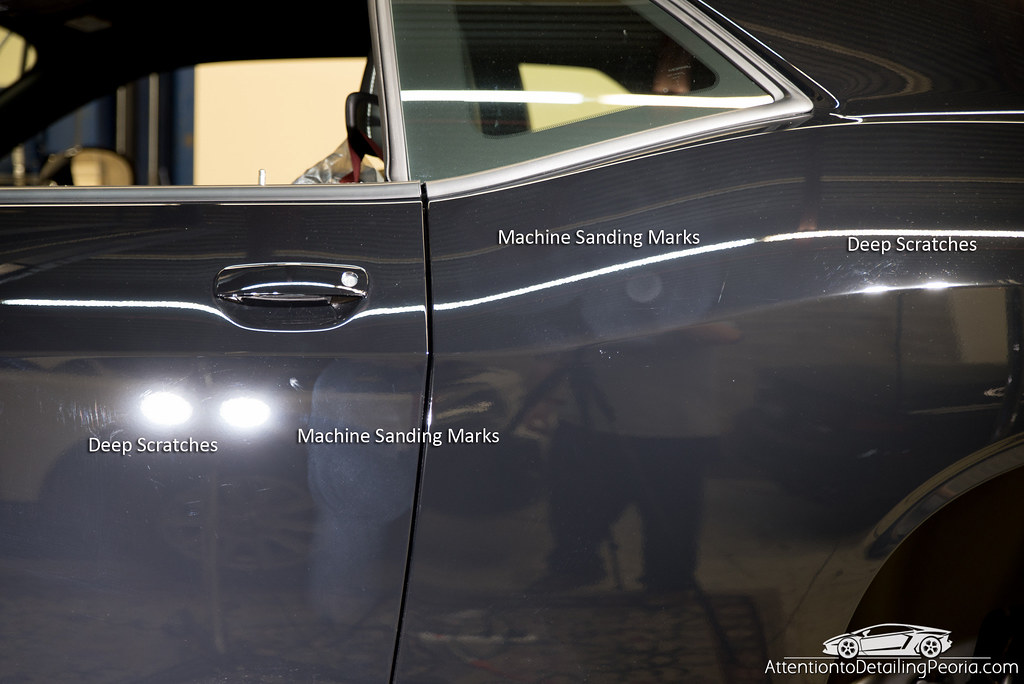

Now it was time to get to work on the paint. Our bright inspection lights made it easy to see what we were up against. In this single photo, you can make out various defects in the paint. Clusters of deep scratches and a lot of machine sanding marks were our major concern.

Given the amount of defects found on this brand new car, it was decided that a multi-step correction process would be used throughout the entire vehicle to level the majority of defects. The paint was extremely soft and sticky which meant there was an impressive amount of marring left from the compounding process.

Obviously this is not an acceptable finish, so we began polishing the paint to remove the haze and reveal a gorgeous finish. This is what sets quality detailers apart from the “other guys”… anyone can run a compound and cutting pad over a paint and call it a day, but it takes skill and patience to perfectly polish soft, jet black paint.

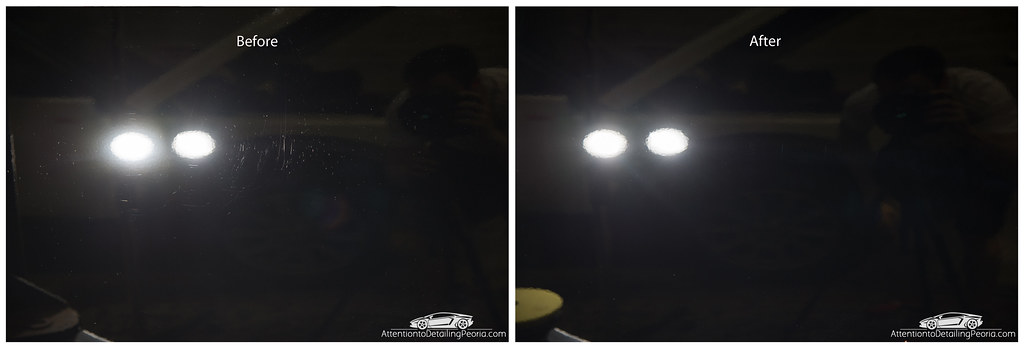

Here are a few before/after shots of various defects that were found. We were able to achieve a nearly flawless finish with only a few deep RIDS remaining.

After the correction and polishing process, the paint was covered with 2 coats of 22ple Mistico Elemento for years of durable protection and gloss.

All exterior plastic was coated with 22ple VR1 to enhance and preserve its appearance. The windshield received 3 coats of 22ple VG1.

The car was pulled outside to inspect the paint after coating, and we were able to see the fruits of our labor… but we weren’t done just yet.

The engine bay received a light cleaning and was then dressed (check out the mirror-like reflections in the doors as well!). All door jams were cleaned, and the interior received a light cleaning as well.

After roughly 27 hours of hard work, this brand new car was ready to be enjoyed by its new owner. We were extremely pleased with the results, and so was he!

Process Overview

- Tires: Tuf Shine Tire Cleaner & Tire Brush

- Wheels: P21S Gel Wheel Cleaner, Wheel Woolies, Wheel Brush

- Wheel Wells: Meguiar’s D114, Various Brushes, Metro Blaster Sidekick, Black All Purpose Towels

- Wash: Meguiar’s Hyper Wash, Bucket & Grit Guard, Foam Lance, Master Blaster

- Decontamination: CarPro IronX, CarPro TarX, Clay Bar, Nanoskin Glide

- Machines Used: Rupes LHR21ES MKII, Rupes LHR15ES MKII, Rupes LHR75e, Griot’s BOSS G21

- Paint Correction: Griot’s Garage Fast Correcting Creme on Griot’s Garage Microfiber Pads

- Polishing: HD Polish on White Lake Country Polishing Pads

- Paint Protection: 22ple Mistico Elemento (available only through authorized professional installers)

- Wheel Protection: 22ple VM1 Extreme

- Windshield Protection: 22ple VG1

- Trim Protection: 22ple VR1

- Tires: Optimum Opti-Bond

- Glass Cleaning: Meguiar’s D120 & Glass Towels

- Engine: Meguiar’s D114, Various Brushes, Black All Purpose Towels, 303 Aerospace Protectant

Buy Products From This Article

Related Posts

- 2016 BMW M4: Paint Correction Detail & 22ple Mistico Elemento Application

- 1999 Porsche 996: Paint Correction and 22ple HPC Coating

- 2015 Range Rover: Paint Correction and Gtechniq Crystal Serum Light Application

- Maserati Granturismo: Paint Correction and 22ple HPC Application

- 2008 CLS 63 AMG – Low Mileage Luxury Beast: Paint Correction & 22ple VX3 Application

I remember when I picked up my new Honda a few years back, before the dealer sent it over to the ‘prep’ department, they removed aplastic film that was attached to all major exterior sections of the vehicle. This indeed protected the vehicle from the harsh contaminants such as rail dust that didn’t require clay job when I took possession of the vehicle.

Dodge doesn’t apply any such any removable protective adhesive to their new vehicles before shipment, especially one of this caliber?

Most cars have a partial protective cover on them that is removed upon delivery to the dealership, but it certainly does not cover the entire vehicle.

Great work. Love to see these results.

Thank you, Tom.

Looks fantastic. Great work on a great car

Thanks!

Thank you for the great article! Very interesting to see the lengths you go to to correct a “new” car. Clients dont realize the amount of hours required to make a new car look “new” ! FCA gives Hell Cats “Special Attention” at the factory so you can imagine the “quality” of lesser models! Hell Cats with the matt black hood are a nightmare. Often sent around for refinishing at the factory.

I have noticed a lot of runs, sanding marks and nibs on Ram’s as well. Time FCA upgraded their paint shops.

Thanks, Doug! This was certainly a bit more than the average new car requires. I can tell the “special attention” due to all of the sanding marks we found throughout.

Beautiful work. Pretty sad, though, that a $70,000 car requires that kind of work. No wonder FCA is looking to get bought out!

Thanks, Dave.

I love those wheels. That is one impressive finished product. Nice work. B&W photo is my fav pic.

I wonder how long a set of rear tires last. I’d have tire rack send out two sets of rears before I pick up the Hellcat. I’m guessing Dodge has seen a few sub 1,000 mile cars that need rears.

Ha, good question Bob. I know I couldn’t resist spinning those tires regularly.

That kind of correction on a new car is more than likely a serious over thought problem. Being said Dodge has very poor paint quality that all the buffing in the world will not fix.

You’re correct… we’ve worked on several new Dodge vehicles and the paint quality has been very poor on all of them. What a shame.

Awesome work. I don’t think I’ve ever seen so much marring caused by a compounding stage! Very impressive to bring out such clarity on the soft sticky paint.

Thank you, Lee. This was definitely a more unique correction process… and certainly one of those cases where “you have to make it worse to make it better” in terms of the amount of marring visible before polishing.

That poor Hellcat looked like it was prepped for delivery by the local high school cheerleader’s car wash fundraiser. You worked magic and made it look proper!

Great Job! I don’t see what product you used to protect the wheel wells. If you used the pro level coating, what would be your recommendation for non-coating protection?

Hi Richard – you’ll notice the list of products used at the end of the article. We used 22ple VM1 Extreme wheel coating to protect these wheels. Our review of this product can be found here: https://www.detailedimage.com/Ask-a-Pro/product-review-22ple-vm1-extreme-wheel-metal-coating/

Car looks amazing!

Wondering if you can help me gain a better understanding on what products to use when. Why did you choose to use a clay bar instead of the nanoskin pad?

Hi Jake – we almost always use synthetic clay products (nano skin or speedy prep towels) due to the time savings, however with the very small amount of contaminates that were on this vehicle, it was just easier to use a clay bar… also, I was experimenting with a new prototype clay 🙂

Looks Great! I had the exact same experience with a brand new Hellcat in the shop. Factory sanding marks. It looked like a spotted cow.

HUMP

Ha, I think I made the same comment about it looking like a spotted cow when we were working on it 🙂 It’s nice that the factory takes some time to chase smaller defects with spot sanding, but you would imagine they might also want to polish them out afterwards. Guess not!

Great review and great job as always Zach!!! Love this car!!…I agree with Mark Wetty, I own a 2014 srt8 challenger and the paint is quite soft and paint quality is poor indeed ..I do everything correct (or at least I think I do) from pre foam to using 50 microfibers practally soaked in Spray wax to prevemt dry scratching in the drying phase and I still manage to find micro fine scratches in between fine polishing ..am I doing something wrong??..I almost feel like they appear magically to drive me crazy hahaha..

Hey Frank – it sounds like you’re doing all you can. The unfortunate thing is that with any vehicle, if you touch it, it will never stay perfect. It is as simple as that. All you can do is minimize the amount of damage that is done over a given period of time by using quality products and technique. If you wanted to save yourself a little headache, a spotless water system would allow you to completely avoid the drying process which is the part of the process that has the highest risk of introducing scratches. Check out CR Spotless De Ionized Water Systems: https://www.detailedimage.com/CRSpotless-M30/

Thanks for the reply Zach!!..I’ve heard great things on the DI water system….I will have to give that a shot..thanks man you’ll hear from me again..much love from hermosa beach, Ca

I hope Dodge knows what those In Ontario have done to their prized jewell. It all looks very suspicious. Although retired now I did call on all of the big three for close to 40 years. Most of my time was in the paint departments. You have done a great job ‘covering’ up for them. It appears from the photos that due to the damage of the paint that it was deliberate. I cannot see any assembly plant allowing something like this to be shipped. I hope that the dealer was notified as well as Chrysler in Auburn Hills Mi and Fiat. Also the deep scratches almost appear to be very long close to 1.5 to 2′ long indicating that this was perhaps below the clear coat and into the sheet metal itself and could have been put in by a fiber disc repair gone bad. I just can’t see this vehicle leaving a assembly plant in this condition. if you were able to buff this out all I can say is wow! The other machine scratches are less obvious to me. The 24 miles on the odometer with the flair out of mud looks like someone hit a pothole. Looks like a little test drive was in order. Happy to see that this can be repaired.

Hi Don – unfortunately this is not uncommon. If you search the detailing forums for other Challenger Hellcat write ups, you will see that many of them arrive in this condition. Thankfully the majority of the damage is repairable.

Hi Zach, the 22ple Mistico Elemento says only available through authorized installers, how do I find one in my area? south texas region.

Hi Chris – I would reach out to 22ple at 22ple.intl@gmail.com If there is an installer in your area, they will be able to point you in the right direction.

What did you charge that fellow?

Without looking back through my invoices, I believe this was a $1500-$1700 job.

Amazing results. Very nice work and nice foto report. I am going to try some microfiber pads this weekend on a black pearl BmW E36 coupe hope to get same results.

Mobile Pro Detailing. Spain/Barcelona

Instgram: Mobile_pro_detailing

This is the best paint correction i’ve seen on a black Challenger! You’ve definitely made this new car look new lol. I’m curious to know why did you choose the regular white flat lake country pads over the CCS lake country? Isn’t the CCS better?

Hi Greg – thanks for the kind words! Regarding pad selection, and really any detailing tool, I always operate under the impression that the “right” tool is the one that does the job you need it to do. I’ve found the good old fashioned flat pads to work very well for me in almost every instance, so I have yet to adopt the newer foam options as I simply haven’t felt the need.