2008 Lexus LS460L

by Todd CooperiderThe owner of this beautiful car contacted me the very day that he received his AutoWeek magazine in the mail and saw me listed in the detailing article. Given the fact that my new website had just gone online days before the article hit, the timing couldn’t have been better.

This is the flagship vehicle for Lexus, and they are stunning cars to say the least. Not only does it have about every creature comfort and gadget available (and a rockin’ Mark Levinson audio system), but it also boasts a V8 with 380HP and 367lb-ft of torque! And it is huuuuge. There is a tremendous amount of surface area to work on with this car.

He told me that he had a 10 month old 460L that needed some TLC to bring it back to life. After meeting with him and inspecting the car, we decided to go for a full correction polish (or as close to as we could get), and to thoroughly clean the interior that was showing some severe signs of wear already. The paint had moderate swirls and RIDS on the horizontal surfaces, mostly mild on the vertical surfaces, and a few scrapes, bumps, and bruises throughout. We planned on the full correction this time, and then he’ll bring it back to me every 3 or 4 months for a more basic polish.

OK, onto the detail(s):

The car looked as expected after a long hard winter here in Ohio. It was quite dirty inside and out, there was no protection on the surface, and it had a tremendous amount of brake dust built up:

The interior was in pretty bad shape as you can see:

Winters do very bad things to light colored carpet…even when using all season mats! There was a hole worn through on this mat, and all of the dirty slush melted through and completely soaked into the carpet underneath. This would be a challenging cleanup for sure.

Here’s where I was concerned. There was a lot of dye transfer into the leather. The grime would come up easily, but there was so much colored dye in this light leather, that I wasn’t sure how much I could get out. Yes, this is only 10 months old.

Even the passenger side was bad. Not only was there makeup on the seating surface, but it was all over the passenger compartment (armrest, door panel, headliner, sun shade, etc).

380HP beast tucked away neatly in a “gentlemen’s car”.

Now it’s time for decontamination and cleaning of exterior surfaces.

I started off with P21S Wheel Gel on the 19″ rims, and let it dwell for a while to work into the many months of brake dust buildup. Here’s a photo of the P21S doing its job:

Once the wheels/wells were completed, I moved on to the rest of the vehicle. First I gave the car a thorough rinsing, and then broke out the foam gun that was loaded with Chemical Guys Wash & Clear mixed at paint-prep ratio (2oz / gal). While this was dwelling I prepared my two wash buckets with CGWC as well. Although I was confident that there was no sealant or waxes remaining on the surface when I received it, I always use the paint prep ratio of CGWC before polishing just to be sure any LSP’s are stripped off.

After the wash process was completed, I pulled the car back inside for claying to remove the embedded contaminants. Since we were just coming out of the winter months, it was a perfect time for claying since I usually find paint to be in the worst shape after winter.

I had the car for several days, so it gave me the opportunity to break up the work a bit. I took this opportunity to try some different products and techniques on the leather. I tried all of the normal routes first on the dye transfer problem. I was able to clean the grime from the surfaces, but the dye was simply laughing at me. This was a perfect time to break out the Leatherique since it would be able to soak in and work for plenty of time. You can see here where I have applied the Rejuvenator Oil to the seats, the armrest, and the door panels (shiny areas).

While the Leatherique was working, I figured I’d test the process and products on the hood before calling it a night. This method works well for me so that when I get up early the next morning to start polishing, I already know what needs to be done. I found that Menzerna PO203S worked well at removing the defects and leaving a very nice finish on the soft Lexus paint. PO203S has a medium-level cut just below that of Super Intensive Polish, and finishes out almost as good as 106FA.

After:

Closeups of the hood:

After polishing:

Day two:

Moving down the side of the car, I found that PO203 Power Finish and a white LC pad worked just fine. A few deeper rids required 2 passes, but other than that just one pass did the trick.

Around to the back of the car, I knew that the trunk lid had deeper defects than the hood. For this one I used Menzerna Super Intensive Polish (SIP). That left some holograms, so I finished it up with 106FA and a grey finishing pad

Before polishing:

After:

Not only does Menzerna make great products, but their bottles are also perfectly sized for propping the trunk lid open when working on the lower areas. It’s smart to do this when working on the trunk lid and the upper part of the bumper to avoid any accidents when moving the rotary around in these tight areas. Here I am using a 4″ white spot pad with PO203.

Moving my way around to the right rear of the vehicle I have some long scratches and paint transfers to deal with. Some of them were easy to remove, while others were pretty deep. Here I went back SIP for a couple of passes, and followed up with 106FF.

Not what you want to see on your 10 month old, $75K car!

All better now:

Here’s just after finishing this side with PO203/white LC pad.

I’ve got everything completed now and cleaned up a bit. I’ve topped it with Opti-Seal, but no LSP as of yet. Here are some after shots in the garage. I have the car for one more day, and it’s supposed to be sunny so I’ll wait and get a few more outside-sun pics at that time.

Wheels all cleaned up and sealed.

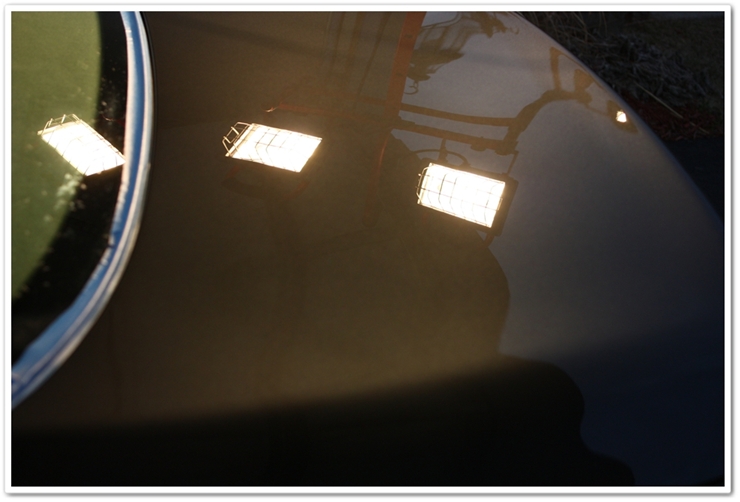

In this reflection shot you can see my new 4-bulb, T-5 fluorescent lights. I put 3 of them in the garage, and they’re a tremendous help.

Here’s my Salvador Dali shot for those artistically inclined. Look at the bending of the clocks in the reflection:

I’ve been waiting all winter to take this shot. I did a lot of these hood/ceiling reflection shots last year before the ceiling was finished. Not only did I complete a major garage makeover, but I also had my logo printed in reverse so I could hang it on the ceiling. Once I take the reflection shots, the logo reads the right way! Pretty cool, eh?

Now that I’ve kept you for this long, and you’re still reading and checking out the photos, I’m going to do my best to keep you a little while longer!

Before I move onto some sun shots, I’m going to show you how the interior turned out. While I was able to get the leather MUCH cleaner, a lot of the dye transfer simply would not come out…no matter what I tried. I was a little bummed about this, but it still looked fantastic in comparison. All interior surfaces were cleaned first with Woolite/water. After that I went after stubborn scuffs and smudges with APC+ at 10:1. The wood and metal trim were polished with Klasse AIO.

I spoke with George at Leatherique about the seating surfaces. After looking at the photos and some Q&A, he confirmed that the surface has been compromised and worn (it was actually rough to the touch in those areas), allowing the dye to transfer deeply into the fibers of the leather. He said that it would require a re-dye in those spots to correct it.

Got legroom?

Remember how bad this area looked? The carpet was cleaned, agitated with a stiff brush, and extracted with hot water. The pedals and foot rest areas were scrubbed with APC 4:1 and a brush. There’s a little bit of staining that was too tough to completely remove, but in the end it was a huge transformation.

Now for the after shots in some sunshine!

Remember what the rear bumper looked like when I received it? (Go ahead and scroll back up to the top…I’ll wait).

I polished up the exhaust outlets with Klasse AIO

No more defects on the trunk lid:

Or on the hood:

This wasn’t a good photo, but I put it in anyhow because I captured an airplane in the reflection! I heard it coming, and waited until it flew underneath the cloud so it would be easier to spot.

When the owner came and picked it up, he couldn’t believe how it looked. He said he was expecting it to look nice, but nothing at the level that he received.

Total time = 12+ hours. The look on the owner’s face when he came to get the car = priceless!

Thanks for taking the time to review my work.

If you have any additional comments or questions, please submit your reply in the comment box below.

[…] out easily. The longer they stay there, the harder it is to remove! Here is a write up by todd @ 2008 Lexus LS460L – Detailed Image that highlights the use of leatherique to remove some stains, but they don't go away completely as […]

Thank you for this article, it is very much appreciated. I’m surprised I’m the first comment on this November 2009 article, since it’s March 2011 now. Did you do an IPA wipedown in between the different polishes?

The M105/M205 article at https://www.detailedimage.com/Ask-a-Pro/polishing-how-to-with-meguiars-m105-m205/ leaves me with 2 questions:

1) For the light defects on the hood, I was wondering why you used P0203S+White pad instead of M105+White pad and then M205+Black pad. Did you finish the P0203S with anything?

2) For the heavier defects, I was wondering why you used P083 (pad not specified?) and then PO106+Grey pad, instead of M105+Orange pad and then M205+White pad.

I have similar defects on my 2002 Lexus LS and would like your opinion on the best approach, given the knowledge available today.

Thanks again!

Stan,

It’s hard to remember the specifics or thought process on a car that I did so long ago, but I’ll give it my best.

The goal on this car was to get as much correction on a one-step as possible. If you read my article on the different types of one-step processes, you’ll see more on this subject and why I would have chosen PO203S.

I’m sure I did some testing on this car before getting started, and found that the 203/white combo was a perfect fit for the majority of the vehicle in terms of correction ability while finishing down so well. The one-step process I used would have gone quicker than the 105/205 option.

And for the areas where I did multi-step polishing for the deeper defects…I was obviously in a Menzerna-mode via rotary that weekend and wanted to stick with what was working.

Paint correction and detailing isn’t necessarily a matter of “right” or “wrong” combinations to achieve a desired result. You have to figure out what tools, products, and techniques work best on that particular car, on that particular day, based on what you’re actually trying to achieve.

So on your 2002 LS, I can’t tell you what would work best as there are simply too many variables. Even if I were to work on it, I would have a general idea after it had been thoroughly inspected, but I would try several different combinations to figure out the best process to get the highest level of correction with the best finish in the least amount of time (assuming full correction was on the menu for that car).

And the tools you have available to you will have a big impact on what products and processes you use. Will you be using just a PC, or just a rotary, or both?

I hope this helps.

Todd,

I notice that you use Woolite to clean up interiors on many of the featured detail articles. I’m really curious about this method of cleaning and would like to learn how I can use it myself. Also, what extractor did you use?.

Thanks,

Kris

Kris,

You can mix it at about 10:1 in a bucket with water, and just use a general purpose microfiber cloth to wipe everything down. This is only needed for very dirty interiors. You can also use Meguiar’s APC to achieve the same kind of results (Megs should provide heavier cleaning capability).

I have a large Mytee extractor in the shop, and a small Bissell in my garage.

I use D103 already. Just wanted to find out if it has its benefits over a product like that. I will try it out and see how it works. Detailing is all about experimentation as you very well know, ha ha!

Kris,

Yes…we are experimenting all of the time, which is how we come up with tricks to the trade. Using D103 is probably a better solution than something like Woolite, but it’s nice to have a safe alternative if you’re out of the product that was designed for that purpose.

I have another question that’s kind of off topic. Do you have any marketing strategies/advice for businesses starting out? Any sources you could point me to?

Thanks again

What a job!!! I just purchased my 2011 ls460L about five months ago. Have seen several LSs with swirly paint. Ive learned that using the wrong type towel or buffing pad would do exactly that. Thanks for helping me figure out how to solve that problem if or when it happens.

What kind of lighting are you using? And how many passes does it take to get rid of RIDs?

old but amazing job!