Side Handle Usage on a Porter Cable 7424XP

by Greg GellasA lot of detailers and weekend warriors own a Porter Cable 7424xp. For many of us, it is the main buffer that we use. I am going to discuss the usage of the side handle, or as the instruction manual calls it, an auxiliary handle:

“An auxiliary handle is furnished with the tool. You can install the auxiliary handle on either side of the front housing to facilitate either right-handed or left-handed operation.

Grasp the polisher firmly with both hands – one hand on auxiliary handle and one hand on motor housing.”

Having a second polisher, I have designated my PC for 4″ polishing. I use it for awkward curves on a body panel, and for tighter areas. If I installed the side handle it would most certainly get in the way many times.

In fact, I have never used the side handle while using the PC, even when I was using it with 5.5″ pads. The main issue is that while light pressure is needed on the pad, using the side handle could cause uneven pressure on the pad. This means you would “tilt” the pad to which ever side you have installed the handle. Although, I did find my side handle, still in the bag and never opened.

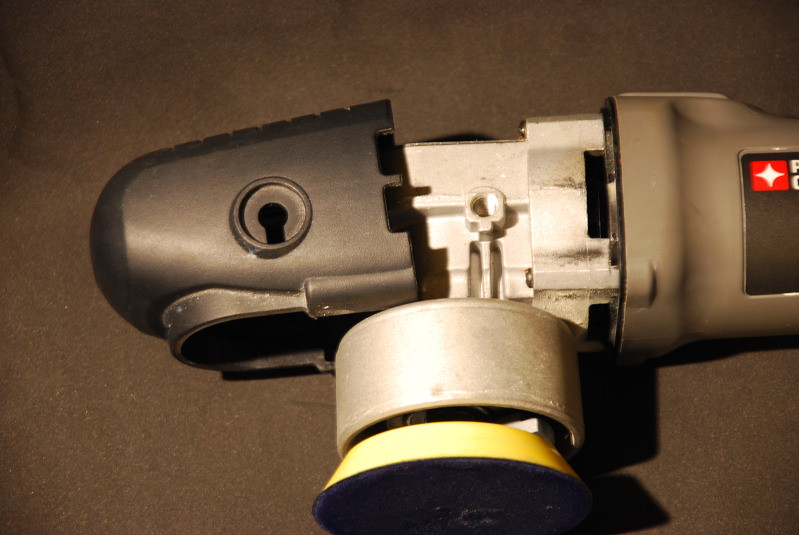

I opened up the bag and installed the side handle to demonstrate why I never have used it. As you can see in the photo below, the natural tendency with the side handle is to bias whichever side the handle is installed on. I tried to keep even pressure on the pad and this was a candid shot that shows even while trying to keep even pressure, it wasn’t. This uneven pressure was causing the pad to stop spinning, not what I wanted.

I opened up the bag and installed the side handle to demonstrate why I never have used it. As you can see in the photo below, the natural tendency with the side handle is to bias whichever side the handle is installed on. I tried to keep even pressure on the pad and this was a candid shot that shows even while trying to keep even pressure, it wasn’t. This uneven pressure was causing the pad to stop spinning, not what I wanted.

Instead, I just use the top of the machine for one hand and my other hand on the motor housing. It allows for proper pressure directly on the pad. Here is DJ Mayo showing this technique.

Without the side handle installed, the top plastic housing is just clipped on and can come off rather easily.

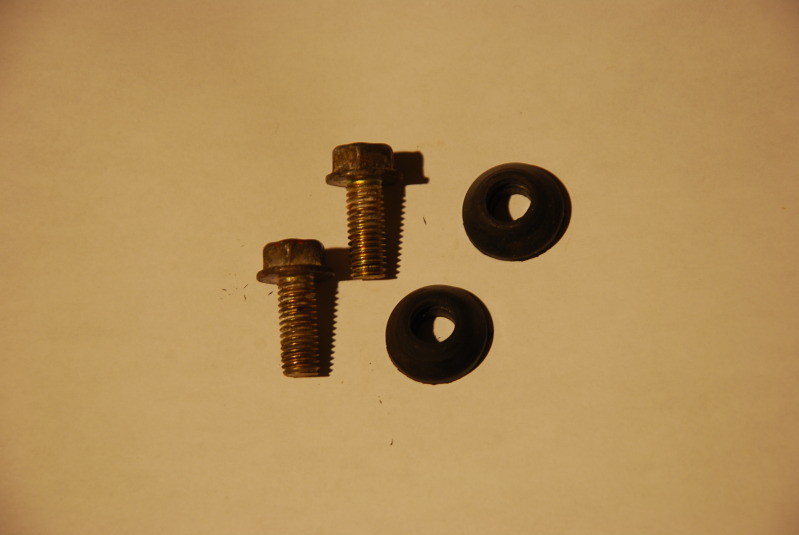

In order to prevent this, I added two bolts with rubber washers to either side of the machine where the side handle would go. I went to a local “box store” with my machine and found these.

These bolts ensure the cover is secured to the body. In addition to the housing being secured, I have found that with the rubber washers and bolts installed, vibrations in the machine are reduced.

I think the reasons that many manufacturers are changing to a D style handle are fairly clear. They allow for more even pressure on pads and are not as intrusive as a side handle. Personally, I do not use the D handle on my second machine. Instead, I have installed the washers and bolts in that machine, gaining the reduction in vibrations and allowing for direct top pressure on pads.

Related Posts

- Polishing Products Part 1 – My Experience With The Rupes Polishers And Others

- The Many Features Of An Entry Level Beginner Polisher

- Beginner Paint Correction Kit: Getting Started on a Budget

- Having The Right Tool For The Job

- Window Etching & Stain Removal | Getting the Most Out of Your Meguiar’s Cutting Discs

Greg,

Didn’t think to bolt the cover on to get rid of the rattle, great tip! I’m going to try to find plastic bolts or use molding clips as I could see myself dinging a mirror or spoiler with a metal bolt. Or, I’ll just cover the metal bolts with some electrical tape.

“Why does Ruprict have a cork on the end of his fork?” *gouge* “oh!”

Great idea Greg!

I’ll have to add bolts on my PC for sure. The plastic cover is always sliding around! I really don’t like using the D handle on my GG DA either…

Greg,

Thank you very much for the detailed article. Most of us do not prefer the handle on this machine for the reasons you pointed out, so this is helpful information.

Here are some more specifics relating to the thread sizes for the 7424xp that may be helpful to everyone wishing to perform this mod:

The 7424 XP currently uses two different bolt sizes depending on the manufacturing date.

If the date code is 2009-10 and earlier try a 5/16-18, 1/2″ long.

Newer units should have a M8x1.25, 1/2″ long.

Personally I prefer a hex head bolt with a washer for a lower profile and cleaner look.

Greg,

Good call on the bolts! I’ll have to do that to my PC, as I dont attach the handle and the top does come off rather easy. Also glad to see you representing Northern NJ! I’m only a few miles north-east of you.

Buddy,

I would suggest trying both a rubber and metal washer. Sure the metal washer will have a lower profile, but I don’t think it will help with the vibration reduction as well as a thicker rubber washer.

Greg

You might want to google a product called the OneGrip PC which I invented years ago that utilizes “housing bolts” and reinforces the idea of polishing over the head of the polisher. The “housing bolts” is really important for the older 7424’s where the housing vibrates and loosens without a handle in place…the XP’s are less susceptible to this.

Hi Greg,

I made no mention of the washer material. I just supplied the bolt size that may be needed to make it easier for someone to complete the process that you detailed. My reference was to the bolt type itself as a hex head bolt is of lower profile than a standard head bolt. I, as others, have found this to be a very clean way of securing the housing.

Best,

Buddy