Ask-A-Pro: What is “Jeweling” the paint?

by Chad RaskovichI have heard the term “Jeweling” to enhance the gloss. How is that done?

Thanks for taking the time to submit this excellent question David!

The term “jeweling” is one of many that I’ve seen over years of surfing the detailing boards. Other terms I’ve seen used to describe this same technique are: burnishing, refining, mirroring, finishing, and of course my all time favorite, reflectus maximus! 😉

At the end of the day, these terms are nothing more than catchy words that describe a final polishing step. Personally, I think a lot of the terms were invented as an attempt to make a detailer stand out above the rest, but regardless, it’s just another polishing step and “jeweling” seems to be one of the more commonly used terms these days.

As far as paint correction goes, jeweling is really considered an optional step as most customers would not be able to see the benefit, nor would they be willing to pay for it. When performed by me, it is almost always done on special interest cars for owners who can appreciate the extra effort, and simply want their cars to look their absolute best regardless of cost! This added step takes a lot of added time and patience, but the end result can definitely turn some heads!

Prior to jeweling the paint, you should have already completed all the necessary correction steps, leaving a finish that is swirl and defect-free. Jeweling simply nets that extra 1-3% gain in appearance you are seeking. This technique is most commonly performed by using a rotary polisher equipped with a zero cut pad, such as the LC black, blue, or crimson pads, and a very fine diminishing abrasive polish like Menzerna 106FA, or PO85RD. You will want to work the product similar to your typical diminishing abrasive polish while being sure to keep your work area to around 20″ x 20″. Start by spreading the polish evenly over your work area at 600-900 rpms. Then bump your speed up to 1500-1800 rpms, making overlapping passes while using firm and consistent pressure. Continue working the polish until it starts to become clear, then reduce pressure and make a few more passes at about 1200 rpms. Finally reduce your speed down to 900-1000 rpms and use only the weight of the machine for a few final passes. Now that your polishing is complete, wipe off excess polish oils with a clean, high-quality MF towel and enjoy your perfect shine! 😉

On a side note, it takes years of practice to master the rotary polisher and even for some of the most experienced users it can be difficult to finish down hologram free. If you are inexperienced with a rotary, similar results can also be achieved with a DA polisher using the same zero cut pads and ultra fine polishes. Also keep in mind that all paints are different so it’s best to experiment with different tools, pads, and polishes to see what works best for your particular finish.

I hope this answers your question. If you or anyone else has any additional comments or questions please submit them in the comment box below.

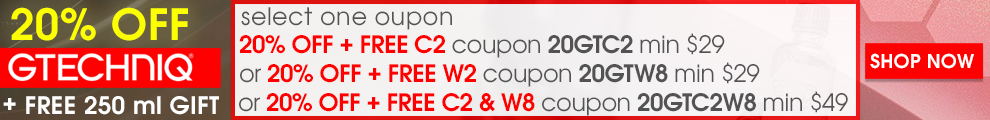

Buy Products From This Article

Purchase the products used in this article individually or in one convenient package here!

Related Posts

- Ask-A-Pro: Polish Recommendations for Acura and Honda paint

- Ask-A-Pro: New to Detailing and Want a Buffer. PC 7424XP? Flex XC3401 VRG? And What About Polishes?

- Ask-A-Pro: Spring Prep on a BMW. Menzerna Polish and Blackfire Wet Diamond?

- 2006 Acura TL in Nighthawk Black Pearl (part 2)

- Compounding / polishing: The looks of the process from start to finish.

Chad,

Thank you for the explaination, it was informative and very much appreciated.

No problem David! Thanks again for the excellent question.

I actually created a poll on one of the detailing boards for fun back in 2009 just to see what term most people use to describe this method. Finishing was actually on top with 63% of the votes and reflectus maximus was second at 11%. 🙂

Rasky

Nice write-up Rasky…thanks for sharing.

Nice write up Chad!

Thanks Jesse! 🙂

Chad:

PO85RD and 106FA are refered to as a diminishing product(s), I assume they brake-down?. But M105/M205 don’t break down? Is this something important to know?. Also, how much of a finishing product do I put on my pad?…Thank in advance!

Great question Steve! Something I probably should have noted in my original article too. 😉

Meguiar’s M105/M205 are indeed non-diminishing abrasives, and they will not break down like traditional diminishing abrasives (106fa/PO85RD). While M205 is highly capable as a jeweling polish, I do find it requires a little bit more of a learning curve, and the technique may vary more from car to car. Because of this I often suggest people stick with the traditional diminishing abrasives for jeweling unless they are willing to put in the time to learn how M205 works.

Since the tiny abrasives in M205 don’t break down they will continue to cut as long as you want. The amount of cut can vary quite a bit depending on pad choice and the amount of pressure you apply, which makes M205 a much more versatile polish. I actually prefer to use M205 with the D/A polisher when used for a final jeweling step, but I’ve also used it with the rotary on many of my jobs too. I’ll use a black LC pad for harder paints and the crimson LC Hydro pad for softer paints.

Since this is a jeweling step, you really shouldn’t need more than 4 pea sized dots on the face of your pad per 20″ x 20″ section.

Hope this helps,

Rasky

Thanks Chad…

Great explaination and advice on Jeweling process. I’ve see alot of your great work!! Can’t wait for the next project…Good Luck and Thanks again.

My question Chad is doing this process going to gain anything on a non-metallic light colored car or should I just stay with a good polish then wax / seal ?

Thanks I always value your opinion..

As always great info here…

Ken

Not sure if anyone looks at these posts anymore but my question is…is jeweling safe on ceramic coating over clear bra? I have a detailer that claims he can take out some of the light surface scratches my dealer service visit left on the car. He says that jeweling is safe for these protective coatings.

Find another detailer.

If he’s using a polish with abrasives it will remove or comprise the integrity of the coating. However, CQuartz Essence Plus is designed for coating maintenance and has no abrasives. Polishing with this product will FILL in light marring. Keep in mind the pad itself is abrasive and Essence Plus is meant to be used with the CarPro Gloss Pad or similar. Too aggressive of a pad and it can comprise the coating regardless of the fact that Essence Plus doesn’t have abrasives.

If you’re seeing marring after a dealer visit I’m going to go out on a limb and say it will likely require a repolish a recoat.

Is your clear bra not self-healing? If it was done in the last couple years it should be if it was applied by a reputable shop.

Hope this helps,

Rasky